Centrifugal clutches are integral to the operation of various machinery and vehicles, from small gardening tools to motorcycles and small vehicles. They automatically engage and disengage the engine's power to the drivetrain based on the engine's RPM, ensuring that your engine delivers power when needed and idles safely when not. However, like all mechanical components, centrifugal clutches wear over time and require periodic adjustment to maintain peak performance.

Centrifugal Clutches

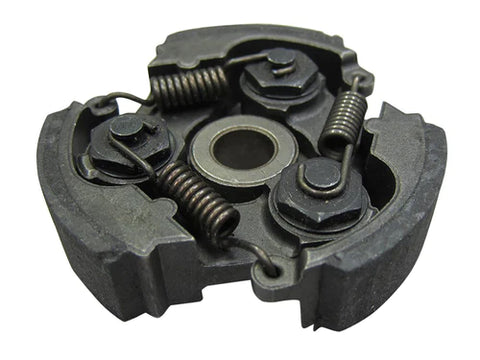

A centrifugal clutch operates on the principle of centrifugal force. It consists of weights or shoes that are thrown outward as the engine's RPM (Revolutions per minute) increases. At low speeds, springs hold the clutch shoes in, disengaging the drive system. As the engine speed rises, the centrifugal force causes the shoes to expand outward, engaging with the clutch drum and transmitting power to the drivetrain.

The centrifugal clutch serves two primary functions:

- Automatic Engagement: It allows the engine to idle without driving the wheels or attached machinery. This automatic engagement and disengagement provide smoother operation and prevent stalling during idle.

- Power Transmission: It smoothly transitions power from the engine to the drivetrain as the engine's RPM increases, ensuring optimal power delivery and control.

Signs Your Clutch May Need Adjustment

Several indicators suggest it might be time to adjust your centrifugal clutch:

- Slipping: If the engine revs higher than usual before engaging or seems to lose power under load, the clutch may be slipping. This can be due to worn-out clutch shoes or improper spring tension.

- Difficulty in Engaging: If the clutch takes longer to engage or requires a higher RPM than normal, it might need adjustment.

- Overheating: An improperly adjusted clutch can cause excessive friction and heat, leading to overheating and damage to the clutch and surrounding components.

- Unusual Noise: Squealing or grinding noises during clutch engagement can indicate that the clutch is out of adjustment or that parts are worn and need replacement.

Recognizing these signs early and adjusting your centrifugal clutch accordingly can prevent more significant issues down the line and ensure your engine operates efficiently and reliably.

What You'll Need

Adjusting the centrifugal clutch on a 4-stroke engine requires a few specific tools and materials. Ensuring you have everything on hand before beginning the process will make the adjustment smoother and quicker. Here's a list of the essentials:

- Socket Wrench Set: To loosen and tighten the bolts on the clutch.

- Feeler Gauge: For measuring the gap between the clutch shoes and the drum.

- Screwdriver Set: Needed for adjusting the clutch mechanism on some models.

- Gloves: To protect your hands from grease and dirt.

- Clean Rag: For cleaning parts and wiping away debris.

- Manual for Your Engine: This provides specific details on clutch specifications and adjustments. If you don't have a manual, BikeBerry.com often has resources or can advise on where to find one for your specific engine model.

Remember, while these tools will cover most centrifugal clutch adjustments, it's always best to consult your engine's manual for any specific requirements or additional tools that might be necessary for your particular model. Some engines might require specialized tools for adjustment or have specific procedures that must be followed to ensure the clutch is adjusted correctly and safely.

Step-by-Step Guide to Adjusting Your Clutch

Here's how to adjust your centrifugal clutch:

Step 1: Safety First

Before beginning any maintenance on your engine, take the following safety precautions:

- Turn off the engine and ensure it is completely cool to avoid burns.

- Wear protective gloves to safeguard your hands from sharp edges and grease.

- Secure the vehicle or machinery to prevent any movement during the adjustment process.

Step 2: Access the Clutch

- Locate the clutch cover on your engine. This is typically on the side of the engine near the bottom.

- Use your socket wrench set to remove the bolts or screws securing the clutch cover. Set the cover aside to access the clutch.

Step 3: Inspect the Clutch

Before making any adjustments, inspect the clutch for wear or damage:

- Check the clutch shoes for excessive wear or damage. Replace them if necessary.

- Ensure the springs are intact and have not lost tension. Replace springs if they appear stretched or damaged.

Step 4: Adjust the Clutch

The adjustment process can vary depending on the clutch design, but here is a general guideline:

- For clutches with adjustable springs: Use a screwdriver to turn the adjustment screw on each spring. Tightening the screw increases spring tension, which raises the engagement RPM. Loosening the screw decreases the tension, lowering the engagement RPM. Refer to your engine’s manual for the recommended RPM range.

- For clutches without adjustable springs: Adjustment may involve shimming the clutch shoes or replacing the springs with ones of different tension to achieve the correct engagement RPM.

Step 5: Testing and Troubleshooting

After adjusting the clutch, it's essential to test the engine:

- Reassemble the clutch cover and secure all bolts or screws.

- Start the engine and allow it to idle. Gradually increase the throttle and observe the clutch engagement. It should engage smoothly without slipping or noise.

- If the clutch still shows signs of slipping, overheating, or engaging too early or late, re-adjust as necessary, and test again.

Step 6: Final Check

- Once satisfied with the clutch adjustment, perform a final inspection to ensure all parts are secure and in good condition.

- Clean any debris or grease from the work area and the engine.

Maintenance Tips

To keep your centrifugal clutch and 4-stroke engine in top condition, here are some tips to ensure longevity and optimal performance:

Regular Inspection

- Check the Clutch Regularly: Frequent inspections can help catch issues early before they lead to more significant problems. Look for signs of wear, damage, or improper engagement and adjust or replace parts as needed.

- Monitor Clutch Performance: Pay attention to changes in engine performance, especially during clutch engagement and operation. Any slipping, difficulty in engaging, or unusual noises should prompt a closer inspection.

Keep It Clean

- Clean the Clutch Area: Dirt, debris, and oil can accumulate around the clutch, affecting its performance. Regularly clean the clutch area to prevent build-up that can lead to overheating or reduced efficiency.

- Use the Right Lubricants: While the clutch itself does not require lubrication, ensure other moving parts of the engine are properly lubricated to maintain smooth operation and prevent excessive wear.

Adjustments and Replacements

- Adjust As Necessary: Follow the steps outlined in the previous section to adjust your clutch when you notice any performance issues. Keeping the clutch properly adjusted is key to maintaining engine performance.

- Replace Worn Parts: Clutch shoes, springs, and other components wear out over time. Replace these parts as needed to keep the clutch functioning correctly. Always use high-quality replacement parts to ensure durability and performance.

With the right approach and attention to detail, you can keep your engine running smoothly and efficiently for years to come.

Click here to learn How To: Adjusting Your 2-Stroke 48cc, 66cc, 80cc Clutch.